Aeronautical marking: Plane part traceability

Industrial marking for the aeronautical sector

MARKING TECHNOLOGY

Dot peen

This is definitely the best option if you want speed in the process. Additionally, it offers great mark depth with very high reliability.

It also has built-in technology that sets it apart from the rest: there is notfaster aeronautical marking on the entire market.

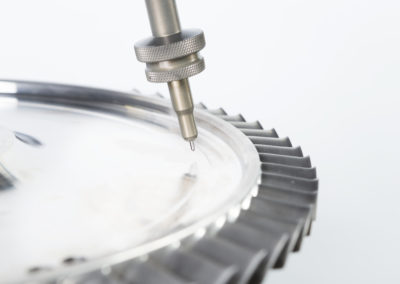

Scribe

This kind of marking for plane parts tends to work and is absolutely necessary for projects that require silent and effective methods.

To mark this way, it uses a diamond or tungsten carbide needle, obtaining very precise results that no other alternative in industrial marking in the aeronautical sector is capable of achieving.

Laser

Marking plane parts with the COUTH® laser is highly valued, thanks to its fast action.

As an added value, it maintains stability and output power, providing a result that lasts over time for all parts.

SECTORS

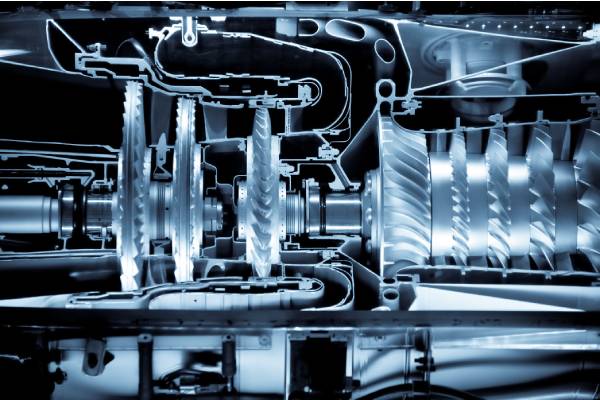

MARKING IN THE AERONAUTICAL SECTOR

COUTH® has different marking solutions for plane parts within the sector.

These services comply with all regulations in the aeronautical sector: ATA Spec 2000 Chapter 9, AS9132 belonging to the ATA and IAQG (International Aerospace Quality Group), as well as NASA standards NASA-STD-6002 and NASA-HDBK-6003.

With this and other factors, we seek high traceability for plane parts. COUTH® offers aeronautical marking solutions that achieve precise legibility for the mark on each part.

PARTS

PARTS FOR THE AERONAUTICAL SECTOR

IMAGES

APPLICATION OF AERONAUTICAL MARKING TECHNIQUES

Applying different techniques to mark plane parts is a delicate process that requires great experience and knowledge of the aeronautical sector, the techniques to use, and the characteristics and needs of each part.

For this reason, COUTH® provides visual examples of the work executed under legal and quality standards.

WHY MAKE MARKS ON PLANE PARTS?

Now that we know the different industrial marking techniques for the aeronautical sector and some of the parts that this latest technology is applied to, we can better understand the advantages of having a specialised company to conduct these tasks.